Kaizen Convention 2019

The 27th annual Kaizen Convention was hosted by SEKISUI S-Lec America, October 21-23, 2019. Traveling from across North America and for the first time, Australia, fifty competitors on 11 teams—as well as 11 judges—gathered at the Hyatt Regency Hotel in downtown Lexington, KY to participate in the event.

The Kaizen projects presented this year offered a wide-ranging look at the very real, day-to-day challenges SEKISUI employees face. Eight were “issue-achieving” Kaizens, and three were “problem-solving” Kaizens. The underlying connection that linked all the presentations was the teams’ shared goal of reducing an adverse element of their business, such as production time, wasted recycled material, and machinery overload.

- The gold-winning team, “Team De-Bottleneck,” from SSCA in Pasadena, TX, discovered new ways to increase production.

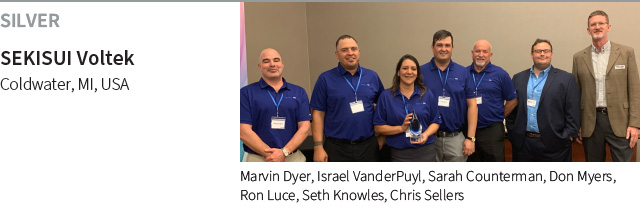

- The silver-winning team, SEKISUI Voltek (“The Eliminators”), searched for ways to reduce voids in their foam products.

- The bronze-winning SEKISUI Diagnostics team, from Prince Edward Island, Canada (“Team BLT”), needed to reduce label production from 32 to 16 days.

- “Team Shield,” the SEKISUI Diagnostics team from California, examined new resources for packaging their product.

- SEKISUI S-Lec Mexico’s team (“Standaction”) looked at ways to reduce time between plant activities.

- “Be Kind, Unwind,” the SEKISUI S-Lec America team, looked for ways to increase the amount of recycled material they use.

- “Method Tweakers,” the SEKISUI XenoTech team, explored ways to manage and reduce machinery overload.

- “Team PIE,” from SEKISUI SPI in Pennsylvania, tested many ways to better control the flow of raw material on their extrusion lines.

- The team from SEKISUI SPI in Michigan (“Transfer Titans”) examined how to reduce the time spent moving raw material from one plant location to another.

- SEKISUI Rib Loc’s team from Gepps Cross, Australia, called “Bruce,” worked to find longer-lasting and more cost-effective tooling solutions.

- At SSCA in Kentucky, the “Calvert City Team” worked to optimize plant turnaround and decrease downtime.

In total, through their focus, diligence, and dedication, the teams achieved a savings and cost-avoidance of over $2.4 million.

This year, winners received a cash prize: $250 for gold team members, $175 for silver team members, and $100 for bronze team members.

Judging was very specific this year

When evaluating the projects, judges were asked to use a set of 16 criteria. “We’re really looking for how closely the project follows the Kaizen methodology,” said judge Drew Olsen from SEKISUI Specialty Chemicals in Calvert City, KY. “And then it’s about how logical the story is and how the presentation flows.”

This year’s winning teams

Harnessing the power of Kaizen every day

“Kaizen impacts every area of our business,” said Michael Ward from SSCA in Kentucky, adding, “It’s not just maintenance or engineering. It impacts everybody. We find ourselves working together, trying to find solutions.”

“In one sense, Kaizen is about perseverance,” Marvin Dyer at SEKISUI Voltek said. “The first one or two counter-measures weren’t so great, but we finally landed on a good one. That’s an important message. Your first idea isn’t always going to work out. Don’t give up.”

Seth Knowles, SEKISUI America Corporation’s Kaizen Manager, summed up the 2019 convention this way: “Even though all the organizations are doing something very different, the reality is that problems and problem-solving are much more alike than they appear in different industries. Kaizen says, ‘Many different problems can be solved the same way,’ and cooperating on how we solve those problems can help us all, no matter how different our organizations feel and are.”